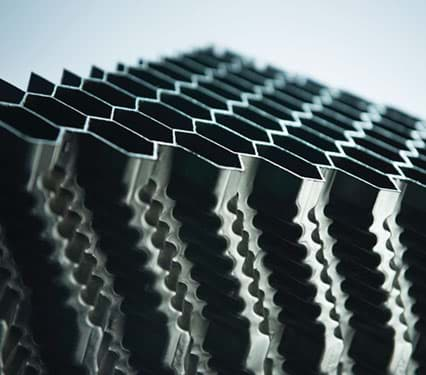

- It is made of environmentally friendly, impact and aging resistant PP (polypropylene) material.

- Provides simple renewal maintenance-repair opportunity under operation.

- It offers the privilege of years of experience in structured fillings for wastewater treatment.

- We offer the service of selecting the most suitable biomedia for your facility and process and configuring it in different variations to suit your individual needs.

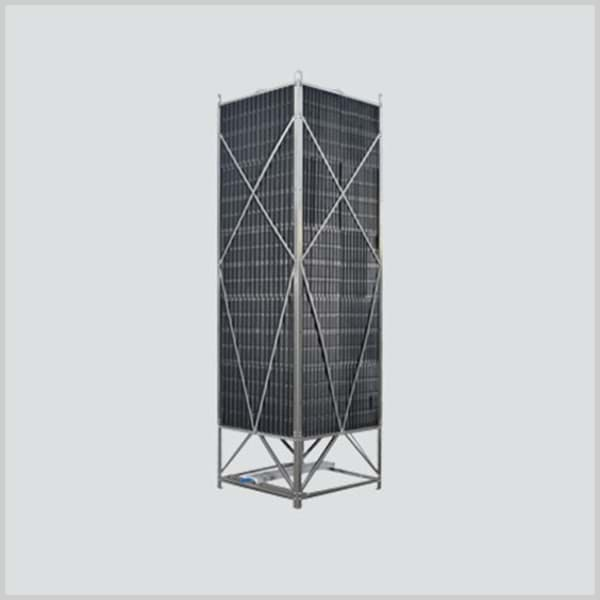

- Perfect for use in low space requirements.

- It gives the system better sludge settling properties.

- Provides optimum surface area for biofilm growth.

- Increases sludge age and active biomass without extra tanks.

- The use of filler media gives excellent results to reduce BOD and achieve low ammonia concentration during nitrification or denitrification.

- Provides maximum system stability as the fixed film is not affected by bulky or punctuated sludge.

- It has much superior features than filters with mineral media (stone, gravel beds) or facilities with expensive floating random media.

- Vertically structured fill biomedia guides and optimizes the sludge and flow rate settling after biological treatment processes.

- Domestic and industrial wastewater is treated economically at an affordable cost.

- The open and special surface structure of our biomedia provides a highly efficient effect. It also allows for larger organic and hydraulic trickling filters or bio reactor loads (submerged and vented) than conventional fills.

- In treatment plants that are new and require minimum space,

- In treatment plant improvements, refurbishment of mineral fillers or random infill media for better performance, to optimize the performance of existing facilities,

- In industrial applications, used to comply with stricter wastewater regulations or to treat larger wastewater streams and dirt loads

.jpg)