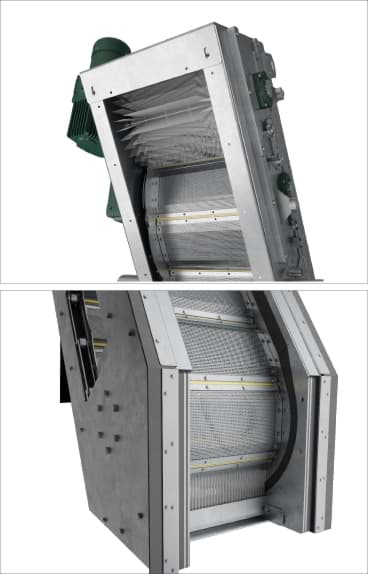

- We have production models that comply with standards for a modern and efficient system of the highest quality.

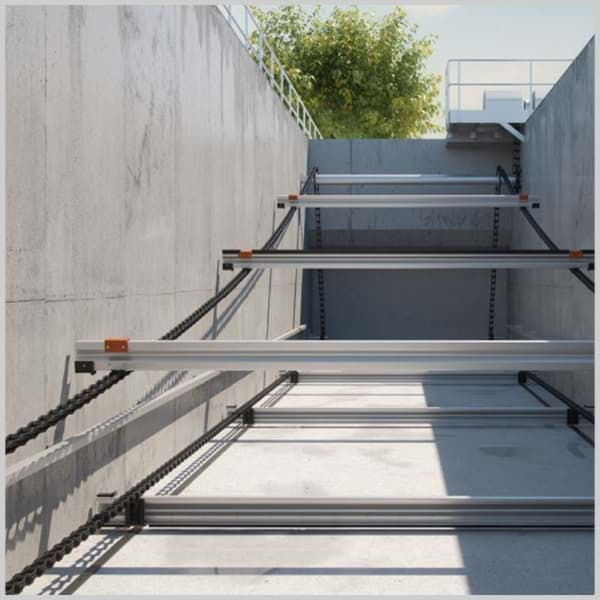

- Our bottom scraper units have a design life of more than 20 years.

- Strong, rigid and torsionally resistant design to the latest standards, in some cases even exceeding these standards.

- Our scraper systems can handle high sludge loads.

- In areas that met water, the product material is AISI304 stainless steel and is used with the AISI316 option as standard.

- Motor, gearboxes, bearings, etc. coated according to customer demand specifications.

- Wastewater treatment plants,

- In industrial wastewater treatment plants,

- Cellulose and paper etc. in factories,

- It is used to further thicken the sludge, which increases its density before settling.

| Power Output | 0.18 – 1.5 kW |

| Motor Gear | SEW, Nord or according to customer request |

| Submerged Steel Parts Stainless Steel Configurations | AISI304, AISI316L, EN1.4547 (Super duplex) S235JRG dip galvanized or GRP grating on walkway |

| Size Configurations | All kinds of configurations are provided. |

| Type | VAT PFT – Picket Fence Thickener;/td> |

| Overload Protection Electronic | Torque limiter ELFI M20 Mechanical |

The motorized gear is mounted on a hot dip galvanized base plate with a mechanical torque limiter; the drive unit is placed on a fixed bridge or concrete slab.

The central shaft is directly coupled to the system and is driven by the drive unit system. The center is made of tubular design and the lower part of the shaft is equipped with a replaceable lower bearing made of polyethylene that runs against a steel stud shaft. The bearing is lubricated with process water.

Horizontal scraper arms with angled scraper blades from the central tube are fitted for bottom scraping to remove all ground surface deposits into the sludge pit in the middle of the tank. Either Mechanical or Electronic, the drive unit comes with overload protection.