- The system takes up little space,

- It does not sting the eyes and nasal. Does not cause harmful effects on health,

- Does not produce dust,

- The money you will spend to transport the product after treatment by truck remains in your pocket (Reduces the cost),

- The energy produced during the process is sufficient for itself,

- Provides phosphorus recovery,

- Investment cost returns in a short time,

- Its capacity can be increased as modular,

- Sludge input at different dewatering rates always produces the same dry product,

- It is environmentally friendly,

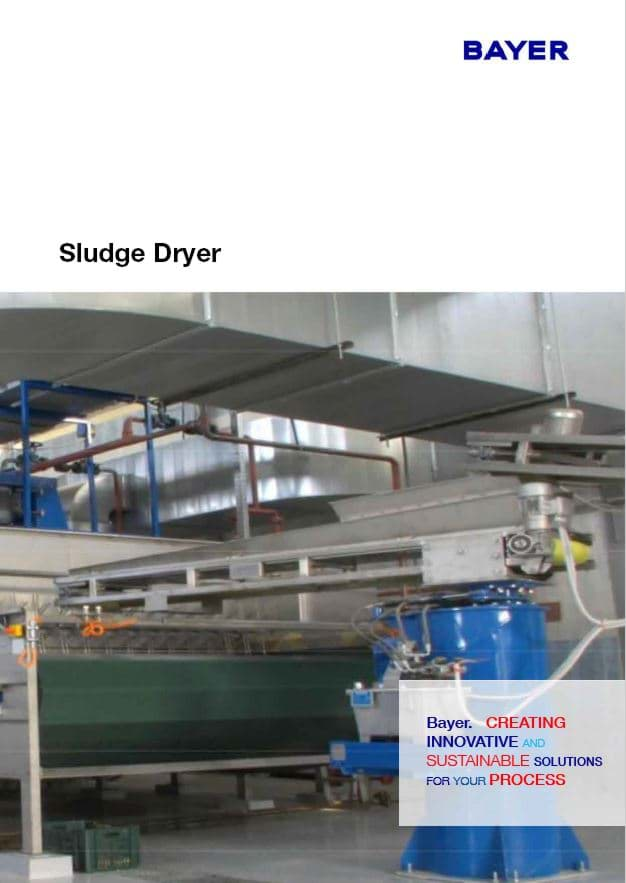

- The system is designed to dry previously dehydrated products and suspensions, which are usually waste or tough waste material,

- It takes action that will reduce the cost of disposal and reduces the volume of waste,

- The drying process is of such a nature that it will produce a recyclable dry product that is suitable for all disposal procedures, resistant to abrasion,

- Since the system works under vacuum, it does not smell to the outside,

- Since the dry sludge is not mixed in the dryer in any way, dust does not form,

- Utilizes "low temperature waste" heat from different processes as an energy source,

- Depending on the calorific properties of the sludge, it can be integrated into a self-sufficient system by returning the waste heat to the system,

- Every single working condition is supervised by modern control programs,

- It has technology that includes ATEX certified regulations,

- The product of the drying process, granulate with high calorific value, is very suitable for other utilization processes such as incineration or gasification,

- Systems have after-sales online monitoring feature,

- Low investment cost systems,

- Systems could work 24 hours a day.

- They are safe processes where there is no risk of explosion and fire,

- HAZOP certified,

- The materials to be dried can be easily stored and can develop almost dust-free granulate quality,

- It can dry the wastewater sludge with 90% efficiency (It does not produce a product other than this efficiency),

- Personnel have the comfort of controlling the operability of the system and ensuring its continuity with very low effort and control time,

- The feeding system can be integrated for changes in the amount of sludge,

- Depending on the amount of sludge formation, its capacity can be increased modularly according to the changing conditions over time.

- Drying of treatment sludge in treatment plants

- For drying fruits and vegetables

- For drying medicinal plants