- You will benefit from the advantage of more than 10 years of experience in advanced anaerobic sludge digestion process and waste nutrient disposal,

- The system offers high engineering quality,

- Provides expertise in sludge processing with advanced and flexible process configuration,

- Provides renewable energy production,

- Provides 2 times more gas production,

- Provides 2 times more electrical energy production,

- Your sludge amount is halved,

- Sludge handling, transportation costs are reduced,

- Operational results of reference facilities; Solids content in dewatered sludge is at least 11% higher than in conventional dewatering,

- Increases digester loading by 2-3 times (Saves capacity. It reduces design dimensions → size and cost of mixer, construction cost decreases),

- Provides Class A sterilization,

- Provides Class A compost,

- It is very effective in sludge dewatering, increases efficiency,

- Reduces sludge processing cost,

- Reduces energy need,

- Reduces product volume,

- No load change is observed in wastewater,

- Provides high speed decay,

- Decreases retention time,

- The system is compatible with small, medium, and large-scale wastewater treatment plants,

- It is designed as a plug and play module.

The sludge line includes all sludge treatment steps in a wastewater treatment plant. Water utilities invest in many different sludge treatment technologies to recover energy or nutrients from sludge, reduce odors, eliminate pathogens, or meet other regulatory requirements.

Most medium and large wastewater treatment plants recover energy from sludge through anaerobic digestion. The resulting biogas meets local energy needs or is sold as electricity or natural gas. Thermal hydrolysis is a sludge treatment technology used in conjunction with anaerobic digestion.

Sludge line design and sludge management practices often have a significant impact on the balance sheet of water services. Cambi makes the difference with the optimum integration of our proven thermal hydrolysis process into any sludge line.

After anaerobic digestion, the sludge is dewatered before final disposal or use. Thermal hydrolysis simplifies sludge management and disposal in several ways:

- As biogas production increases, less product remains to be digested,

- Final dewatering requires less energy;

- The volume of dewatered biosolids is much lower, so they are cheaper to use;

- Dehydrated biosolids are pathogen free, low odor, easy to store and transport.

By investing in thermal hydrolysis, water services often gain new options, such as transporting sludge to farmers for agriculture for biosolids disposal.

In areas where incineration is required, the resulting biosolid product has a higher calorific value, which can translate into lower gate charges.

Thermal Hydrolysis Process Before Anaerobic Digester

Thermal Hydrolysis Process After Anaerobic Digester

i-THP Thermal Hydrolysis Process Between Two Digesters

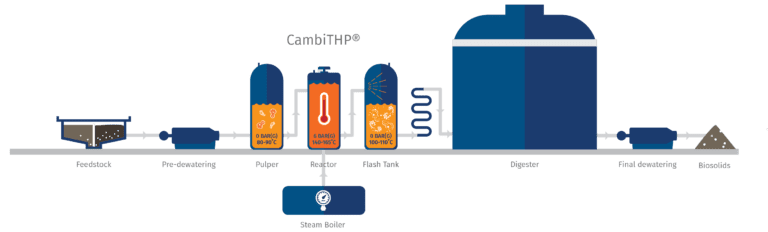

Raw sewage sludge is collected from the primary and secondary treatment units of the wastewater treatment plant and dewatered up to 16-18% dry matter. This thickened sludge is continuously fed into the sludge chamber of the thermal hydrolysis.

The sewage sludge, which is preheated in the pulper, is fed continuously to the reactors, which may be in different numbers depending on the process. In this process, the completely sealed, high pressure and temperature treatment sludge is hydrolyzed in a sequential process.

From the reactor, the instant sterilized sludge is rapidly passed into the flash tank operating at atmospheric pressure. The sudden pressure drop provides significant cell destruction for the organic matter in the sewage sludge.

The sludge separated from the flash tank is cooled to the appropriate temperature for anaerobic digestion, partly by adding dilution water and partly by adding heat exchangers. It is then fed to anaerobic digesters.

After anaerobic digestion, the final product is sterilized and can meet even the strictest regulations for organic waste treatment. To conclude, they are excellent quality biosolids that can be applied in agriculture.

Advantages:

Thermal Hydrolysis, when applied before anaerobic digestion, has the following benefits:

- Significantly supports the biodegradability of activated sludge,

- Allows significantly higher loading rates resulting in smaller digester tank volume requirement. This can save enormous amounts of upfront capital investment in brownfield expansions, rotten refurbishment projects and greenfield projects.

- Increases biogas production rate.

- Sterilizes sludge providing low odor, pathogen free, bio solids.

- Significantly reduces downstream requirements for drying and other thermal processes.

The raw sludge from the primary and secondary treatment units of the wastewater treatment plant is fed to the digesters as in a conventional process.

The digested sludge is then dewatered at 16% DS and fed to the grinder.

From the pulper, the hot sludge is fed continuously into the reactors in a sequential process that ensures sealed sludge batches in each reactor.

From the reactor, the now sterilized sludge is quickly passed into the flash tank operating at atmospheric pressure. Sudden pressure drop causes significant cell destruction for organic matter in sewage sludge.

The centrifuge containing highly concentrated biodegradable material is returned to the digester for additional biogas production.

Advantages:

When applied after anaerobic digestion, thermal hydrolysis has the following benefits compared to conventional anaerobic digestion:

- Increases the performance of existing digesters and existing plants.

- The final product has the characteristics of a sterilized, odorless, highly dry solid mud cake.

- It reduces the volume of sludge cake up to 50% - 60% for waste disposal, making it an ideal solution for projects with high disposal costs and high energy value.

- Typically reaches 40% DM in final biosolids.

- Typically increases biogas production by 25%-40%.

- Provides up to 75% UKM reduction.

THP B-2

The B2 is the smallest CambiTHP model suitable for medium-sized wastewater treatment plants. The B2 is manufactured and delivered as a complete unit on a single skid for up to 4 reactors.

All B2 plants are fully assembled and tested in our workshop to minimize time for installation and operation and to work in the field. This makes the B2 a “plug and play” system.

THP B-4

The B4 model is suitable for medium and large-scale wastewater treatment plants. The B4 is manufactured and delivered as a packaged unit. It is pre-assembled and tested in our workshop. This reduces the time and work required for installation and start-up in the field.

Several sets can be installed in parallel for increased capacity or redundancy.

THP B-6

The B6 model is suitable for medium and large-scale wastewater treatment plants. The B6 is manufactured and delivered as a packaged unit. It is pre-assembled and tested in our workshop. This reduces the time and work required for installation and start-up in the field.

Several sets can be installed in parallel for increased capacity or redundancy.

THP B-12

The B12 is Cambi's largest THP model. It is

suitable for large and very large wastewater treatment plants. Due to its

standard design, test and assembly in the workshop, the installation time in

the field is short.

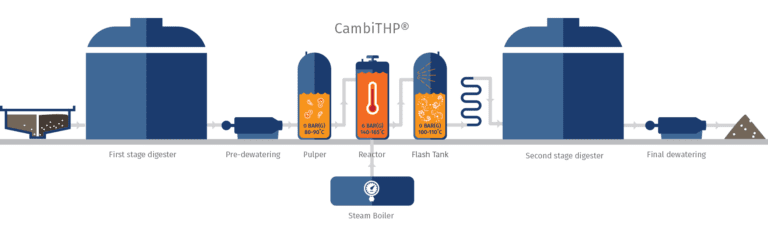

From the primary and secondary treatment units of the wastewater treatment plant, the concentrated raw sludge is fed to the first stage digester(s).

The sludge is pumped from the first stage digester(s), pre-dewatered at approximately 16.5% DS and fed into the grinder. In the pulper, the sludge is preheated with the steam recovered in the flash tank.

From the grinder, the preheated sludge is fed to the reactors in batch mode. After the reactors are filled, steam is added to bring the sludge to the required temperature and pressure.

From the reactor, the instant sterilized and hydrolyzed sludge is passed into the flash tank operating at atmospheric pressure. The sudden pressure drop causes significant cell destruction for the organic matter in the sewage sludge.

The sludge leaving the flash tank is cooled to the typical temperature for anaerobic digestion, partly by adding dilution water and partly by adding heat exchangers. It is then fed to the second stage anaerobic digester(s).

The final product after anaerobic digestion is pathogen-free and meets the strictest regulations for organic waste treatment. The result is biosolids of excellent quality that can be applied in the soil.

Advantages:

When applied between two anaerobic digester stages, thermal hydrolysis has the following benefits:

- Significantly supports the biodegradability of activated sludge,

- Provides higher biogas production compared to THP before anaerobic digestion,

- Sterilizes sludge, providing low odor, pathogen-free biosolids,

- Provides high dry solids content in final biosolids,

- When applicable, significantly reduces downstream requirements for drying and other thermal processes.